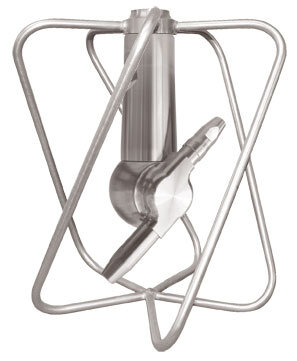

Tornado 2 Orbital cleaner

Extremely powerful, radially and axially rotating jet cleaner with 2 nozzles

- liquid driven 360° low pressure orbital cleaner

- strong radiation with high consumption values

- FDA compliant & EX certified

- acid, alkali and temperature resistant

- compact dimensions

- self-cleaning, hygienic, low-wear

- validatable cleaning

- function monitoring by Vericlean or SMW 100

- for industrial usage

| Technical Data | Value |

|---|---|

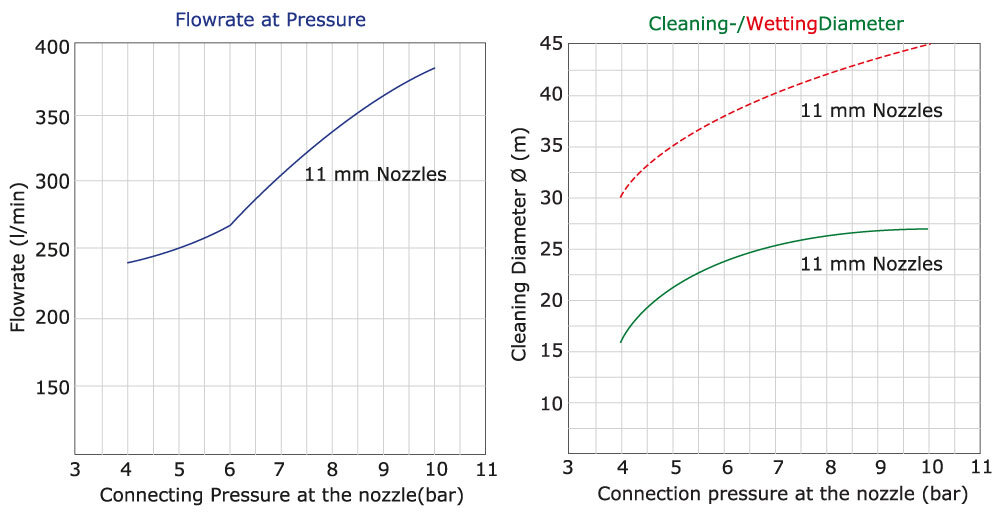

| Max. cleaning diameter: | 27 meters |

| Spray pattern: | 360° orbital |

| Pressure range: | 4 – 10 bar / 58-145 psi |

| Flow rate: | 243 – 378 LPM (14,6 – 22,7 m³/h) |

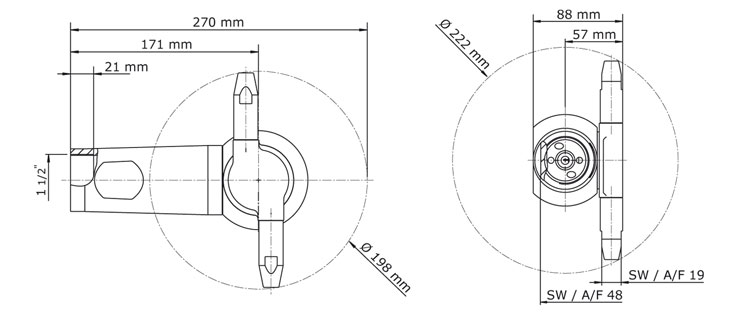

| Insertion opening: | min. Ø 100 / 220 mm |

| Preferred mounting position: | arbitrary, preferrably vertical |

| Weight: | approx. 3,1 KG |

| Materials: | Stainless Steel 316L (1.4404), C.PTFE, PTFE |

| Pipe connection: | 1,5″ female thread BSP (NPT) |

| Optional Pipe Connections: | 1,5″ Splint, DN40 Splint, DN50 Splint, 1,5″ Clamp |

| Nozzle characteristics: | 2 x 11,0 mm nozzles |

| Certificates: | 3.1, 2.2, ATEX, FDA Regulation (EC) No 1935/2004 |

| Max. operating temperature: | 95°C (203°F) |

| Max. ambient temperature: | 140°C (284°F), 30 Min. |

| Operating recommendation: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

Optimal Operation

The pressure range for operating a Typhoon is 4 – 10 bar at the cleaning machine.

With a flow rate of 243 – 378 liters/minute, a cleaning diameter of 10 – 17 meters is achieved.

Connection types

Threaded connection

Tornado 2 standard devices are equipped with a 1,5″ cylindrical internal thread BSP (British Standard PIPE according to DIN ISO 228). The device is optionally available with a 1,5″ conical internal thread NPT (National Pipe Taper, American pipe thread for self-sealing connections).

Splint connection

The Tornado 2 orbital cleaner is optionally available with a 1,5″ splint pin attachment. The splint pin attachment ensures that the cleaning machine is attached without dead space. Splint pin versions have an approx. 15% higher flow rate.

Clamp connection

The Tornado 2 is optionally available with a 1,5″ clamp connection. A clamp connection ensures the uncomplicated removal of the cleaning machine.

Tornado 2 Orbital cleaner – Product Attachment types/variants

Tornado 2 industrial Orbital cleaner with 1,5″ Thread Attachment

| Attachment | Nozzles | Pipe* | Product Code | Materials | Certificates | Article Number |

|---|---|---|---|---|---|---|

| *corresponds to the maximum pipe OD of the pipe on which the machine is to be installed (inches or mm). Splint pin versions have an approx. 15% higher flow rate. Recommended standard devices with a high probability of being in stock are set in blue. | ||||||

| 1,5″ IG-BSP | 2 x 11,0 mm | 1,5″ | Tornado2-AF2x11S-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-4970-113 |

| 1,5″ IG-BSP | 2 x 11,0 mm | 1,5″ | Tornado2-F2x11S-BSP | 316L/PTFE | FDA, 3.1 | 4660-4970-114 |

| 1,5″ IG-NPT | 2 x 11,0 mm | 1,5″ | Tornado2-AF2x11S-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-4970-115 |

| 1,5″ IG-NPT | >2 x 11,0 mm | 1,5″ | Tornado2-F2x11S-NPT | 316L/PTFE | FDA, 3.1 | 4660-4970-116 |

Tornado 2 industrial Orbital cleaner with 1,5″ Splint attachment

| Attachment | Nozzles | Pipe* | Product Code | Materials | Certificates | Article Number |

|---|---|---|---|---|---|---|

| *corresponds to the maximum pipe OD of the pipe on which the machine is to be installed (inches or mm). Splint pin versions have an approx. 15% higher flow rate. Recommended standard devices with a high probability of being in stock are set in blue. | ||||||

| 1,5″ Splint | 2 x 11,0 mm | 38,1 | Tornado2-AF2x11S-150PF | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-4970-117 |

| 1,5″ Splint | 2 x 11,0 mm | 38,1 | Tornado2-F2x11S-150PF | 316L/PTFE | FDA, 3.1 | 4660-4970-118 |

Tornado 2 industrial Orbital cleaner with DN40 Splint Attachment

| Attachment | Nozzles | Pipe* | Product Code | Materials | Certificates | Article Number |

|---|---|---|---|---|---|---|

| *corresponds to the maximum pipe OD of the pipe on which the machine is to be installed (inches or mm). Splint pin versions have an approx. 15% higher flow rate. Recommended standard devices with a high probability of being in stock are set in blue. | ||||||

| DN40 Splint | 2 x 11,0 mm | 41,15 | Tornado2-AF2x11S-DN40 | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| DN40 Splint | 2 x 11,0 mm | 41,15 | Tornado2-F2x11S-DN40 | 316L/PTFE | FDA, 3.1 | – |

Tornado 2 industrial Orbital cleaner with DN50 Splint Attachment

| Attachment | Nozzles | Pipe* | Product Code | Materials | Certificates | Article Number |

|---|---|---|---|---|---|---|

| *corresponds to the maximum pipe OD of the pipe on which the machine is to be installed (inches or mm). Splint pin versions have an approx. 15% higher flow rate. Recommended standard devices with a high probability of being in stock are set in blue. | ||||||

| DN50 Splint | 2 x 11,0 mm | 53,25 | Tornado2-AF2x11S-DN50 | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| DN50 Splint | 2 x 11,0 mm | 53,25 | Tornado2-F2x11S-DN50 | 316L/PTFE | FDA, 3.1 | – |

Tornado 2 industrial Orbital cleaner with 1,5″ Clamp Attachment

| Attachment | Nozzles | Pipe* | Product Code | Materials | Certificates | Article Number |

|---|---|---|---|---|---|---|

| *corresponds to the maximum pipe OD of the pipe on which the machine is to be installed (inches or mm). Splint pin versions have an approx. 15% higher flow rate. Recommended standard devices with a high probability of being in stock are set in blue. | ||||||

| 1,5″ Clamp | 2 x 11,0 mm | 1,5″ | Tornado2-AF2x11S-150CL | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 1,5″ Clamp | 2 x 11,0 mm | 1,5″ | Tornado2-AF2x11S-150CL | 316L/PTFE | FDA, 3.1 | – |

Accessories

Welded adapter

| Materials: | Stainless steel 1.4404 (316L) |

| Certificates: | 3.1, 2.2 |

| Device attachment: | 1,5″ AG-BSP |

| Supply: | Welding end |

SMW 100 Fluid sensor

| Materials: | 1.4305, PEEK |

| Connecton type: | Welded socket |

| Function: | Sensor surge is displayed every 20 seconds. |

Maintenance packages & Toolkit

| Tornado 2 C.PTFE (ATEX & FDA) | 4660-4050-888 |

| Tornado 2 PTFE (FDA) | 4660-4051-888 |

| Toolkit: | 4660-4031-888 |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 17.10.2022-71427321893-1888948-71042)