Jumbo 6 Jet cleaner

Powerful and fast rotating jet cleaner with 4 long nozzles

- liquid driven 360° low pressure jet cleaner

- strong jet power with high consumption values

- short cleaning time

- acid & alkali resistant

- available with 2 nozzle diameters

| Technical Data | Value |

|---|---|

| Max. Cleaning Diameter: | 11 meters |

| Spraypattern: | 360° |

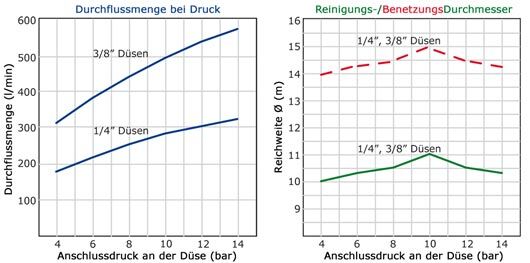

| Pressure-range: | 4 – 14 bar |

| Flowrate: | 1/4″ 180 – 320 LPM (10,8 – 19,2 m³/h), 3/8″ 310 – 580 LPM (18,6 – 34,8 m³/h)) |

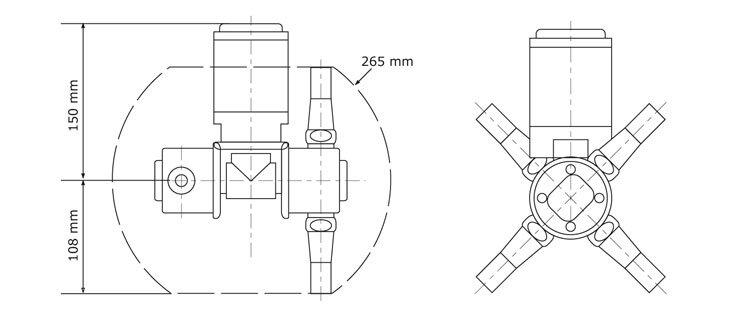

| Insertion Opening: | min. Ø 280 mm |

| Mounting position: | vertikally downwards |

| Weight: | ca. 5,6KG |

| Materials: | Edelstahl 316L (1.4404), PTFE |

| Standard connection: | 1,5″ internal thread BSPT |

| optional connection types: | on demand |

| Nozzle characteristic: | 4 x 1/4″ nozzles, 4 x 3/8″ nozzles |

| Certificates: | 3.1, 2.2, more on demand |

| max. Operating temperature: | 95°C (203°F) |

| max. ambient temperature: | 140°C (284°F), 30 Min. |

| Operating recommendation: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

The JUMBO 6 has a simple and effective drive system that guarantees long service life and good durability. The external gearbox can be visually inspected for contamination and cleaned. The robust design of the JUMBO 6 allows it to be used in a wide range of industries and container types where effective and powerful cleaning is required.

The JUMBO 6 is powered only by the cleaning fluid by causing a simple turbine inside the JUMBO 6 to rotate. All cleaning liquid exits mainly through the nozzle openings, so minimal energy is used for propulsion.

Rotating and static spray balls can be optimally replaced by a JUMBO 6. The strong spraying power of the JUMBO 6 creates a powerful mechanical cleaning effect in tank sizes up to 11 meters in diameter.

Jumbo 6 with 1,5″ BSPT Thread”

| Connection | Nozzles | Pipe* | Product code | Materials | Certificates | Article numbers |

|---|---|---|---|---|---|---|

| *corresponds to the max. pipe outer diameter of the pipe on which the machine is to be installed (inch or mm). Split pin versions have approximately 15% higher flow. Recommended standard units with high stock probability are shown in blue. | ||||||

| 1,5″ IG-BSPT | 4 x 1/4″ | 1,5″ | Jumbo6-4×14-BSPT | 316L/PTFE | 3.1, 2.2 | 4660-4943-110 |

| 1,5″ IG-BSPT | 4 x 3/8″ | 1,5″ | Jumbo6-4×38-BSPT | 316L/PTFE | 3.1, 2.2 | 4660-4942-000 |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 27.10.2023-71427321893-1888948-71042)