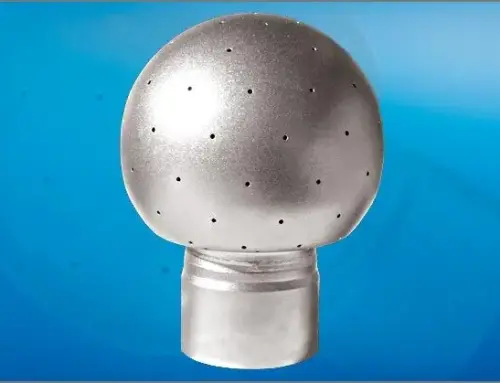

Extremely powerful, radially and axially rotating motor-driven target jet cleaner with 2 or 4 nozzles

- Liquid driven 360° low pressure Orbital Cleaner

- Extremely strong Jet Power and High Flowrate

- FDA compliant & Ex certified

- Acid, Alkali & Temperature resistant

- Compact Dimensions

- Self-cleaning, Hygienic, Wear-resistant

- Calidatable Cleaning

- Function Monitoring with SMW 100

Technical Data

| Technical Data | Value |

|---|---|

| max. Cleaning Diameter | 12 Meters |

| Spraypattern | 360° orbital |

| Pressure Range | 1-25 bar |

| Flowrate | 8,3 – 138 LPM (0,5 – 8,25 m³/h) |

| Insertion Opening | min. Ø 50/96 mm |

| Preferred Mounting Position | arbitrary, preferably vertical |

| Weight | ca. 11/15 kg |

| Material | Stainless Steel 316L (1.4404), PTFE |

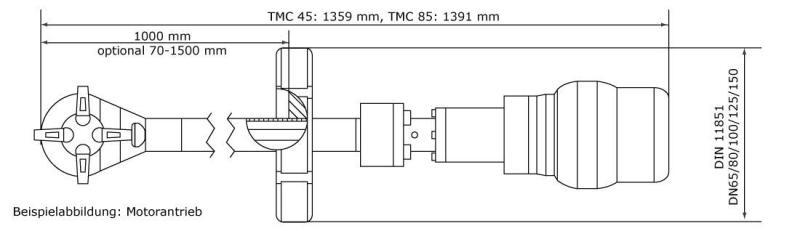

| Pipe Connection | DIN 11851 DN65/80/100/125/150, Swivel and Sliding Flange |

| Nozzle equipment | TMC 45 2 oder 4 Düsen, 2,0 bis 3,5 mm |

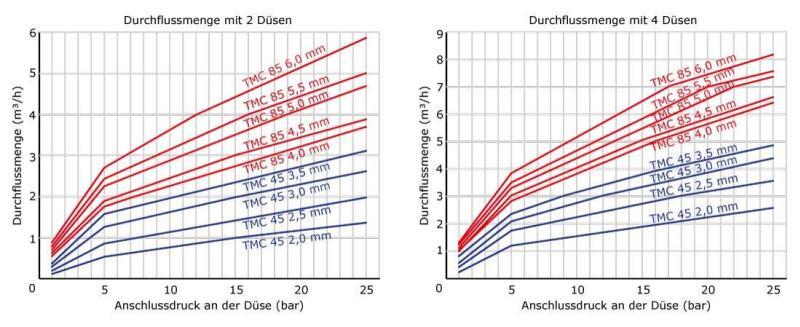

Operating Values

Optimal Operating

The pressure range for the operation of a TMC 45/85 is between 1 – 25 bar at the Cleaning Machine.

With a flow rate of 8.3 – 138 Liters/Minute, a Max. Cleaning Diameter of up to 12 Meters is achieved.

The TMC45/85 is a motorized or pneumatically driven Orbital Cleaner that can be equipped with two or four Nozzles from 2.0 mm to 6.0 mm. Due to a Motor Drive, the Speed of the axially and radially rotating Nozzle Head is independent of the Liquid Flowrate. This allows the Unit to achieve effective Cleaning even with the smallest Quantities of Liquid.

The TMC Orbital Cleaner is available in many Connection Types and Lengths. Optionally, the Cleaning Process of a TMC can be monitored by SMW 100.

Further Information is available on request.

Connection Types

Container Connection

- DIN 11851 KM DN 65

- DIN 11851 KM DN 80

- DIN 11851 KM DN 100

- DIN 11851 KM DN 125

- DIN 11851 KM DN 150

- Swivel and Sliding Flange

Cleaning medium connection

- Welding Connection 21×2,5 mm

- Sleeve R1/2″ Internal thread

- Sleeve R3/4″ Internal thread

- Sleeve R1″ Internal thread

- Nipple R1/2″ External thread

- Nipple R3/4″ External thread

- Nipple R1″ External thread

TMC 45/85 – Product selection/order key

TMC 45/85 Motor driven Orbital Cleaner

| Code | RT_TMC | 45 | 1 | S | 4 | 2 | K | 230 | – | – | – | 0 | 0 | 0 | K |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Position | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| Beispiel | Position | Bezeichnung | Code-Auswahlmerkmale | |

|---|---|---|---|---|

| * Angabe der Einführlänge ** Sonderanschlüsse auf Anfrage | ||||

| RT_TMC | 1 | Typ | RT_TMC = Orbitalreiniger TMC | |

| 45 | 2 | Baugröße | 45 | TMC 45 |

| 85 | TMC 85 | |||

| 1 | 3 | Grundpreis | 1 | Ø 21,3 mm (TMC 45) |

| Ø 33,7 mm (TMC 85) Einführlänge 500 mm | ||||

| 2 | Ø 21,3 mm (TMC 45) | |||

| Ø 33,7 mm (TMC 85) Einführlänge 750 mm | ||||

| 3 | Ø 21,3 mm (TMC 45) | |||

| Ø 33,7 mm (TMC 85) Einführlänge 1000 mm | ||||

| S | 4 | Sondereinführlänge (Aufpreis) | S | Tragrohrverkürzung/ -verlängerung |

| zwischen 200 – 1500 mm* | ||||

| 4 | 5 | Düsenscheibe | 2 | mit 2 Düsen Ø 2,0 – 3,5 mm (TMC 45) |

| 20 | mit 2 Düsen Ø 4,0 – 6,0 mm (TMC 85) | |||

| 4 | mit 4 Düsen Ø 2,0 – 3,5 mm (TMC 45) | |||

| 40 | mit 4 Düsen Ø 4,0 – 6,0 mm (TMC 85) | |||

| 2 | 6 | Düsendurchmesser TMC 45 Düsendurchmesser TMC 85 | 2 = 2 mm; 2,5 = 2,5 mm; | |

| 3 = 3 mm; 3,5 = 3,5 mm; | ||||

| 4 = 4 mm; 4,5 = 4,5 mm; | ||||

| 5 = 5 mm; 5,5 = 5,5 mm; 6 = 6 mm | ||||

| K | 7 | Einsatz | K | kein Ex-Bereich |

| E | Ex-Bereich (gilt für Zonen 1, 2, 21, 22) | |||

| 230 | 8 | Motor | 400 | Antriebsmotor 400V/50Hz; IP55; 1.400/min; 90W (ATEX) |

| 230 | Antriebsmotor 230V/50Hz | |||

| 24 | Antriebsmotor 24V inklusive Schutzhaube aus Edelstahl | |||

| P | Druckluftmotor mit Schutzhaube aus Edelstahl (ATEX) | |||

| – | 9 | Motoroptionen | – | ohne |

| F | integrierter Frequenzumrichter im Klemmkasten des Motors | |||

| – | 10 | Schutzhaube | – | ohne |

| SH | mit Edelstahlschutzhaube | |||

| – | 11 | Handgriff | – | ohne |

| H | mit Handgriff aus Edelstahl | |||

| 0 | 12 | Behälteranschluss** | 0 | ohne |

| 65 | DIN 11851 KM DN 65 | |||

| 80 | DIN 11851 KM DN 80 | |||

| 100 | DIN 11851 KM DN 100 | |||

| 125 | DIN 11851 KM DN 125 | |||

| 150 | DIN 11851 KM DN 150 | |||

| SCH | Schwenk- und Schiebeflansch | |||

| 0 | 13 | Anschluss Reinigungsmedium | 0 | Schweißende 21×2,5 mm |

| 1 | Muffe R1/2″ Innengewinde | |||

| 2 | Muffe R3/4″ Innengewinde | |||

| 3 | Muffe R1″ Innengewinde | |||

| 4 | Nippel R1/2″ Außengewinde | |||

| 5 | Nippel R3/4″ Außengewinde | |||

| 6 | Nippel R1″ Außengewinde | |||

| 0 | 14 | Oberfläche | 0 | Ra < 0,8 μm geschliffen (ohne Schweißnähte) |

| 1 | Ra < 0,4 μm elektropoliert (ohne Schweißnähte etc.) | |||

| K | 15 | Zertifikate | K | ohne Zertifikate |

| W | (41) mit Werkzeugnis 2.2 DIN EN10204 | |||

| Z | (42) mit Material-Abnahmeprüfzeugnis 3.1 DIN EN10204 | |||

| A | (41/42) 2.2; 3.1 | |||

Accessories

SMW 100 Fluid Sensor

| Materials: | 1.4305, PEEK |

| Connection type: | Weld-in socket |

| Function: | The surge of the sensor is displayed every 20 seconds |

Maintenance Packages & Tools

| TMC 45 Machine head | 254-000537 |

| TMC 85 Machine head | 254-000538 |

| TMC 45/85 Coupling | 254-000539 |

| Toolkit TMC 45: | 254-000566 |

| Toolkit TMC 85: | 254-000568 |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All data are without guarantee. (Stand: 22.10.2023-71427321893-1888948-71042)