Spinner ball bearing nozzles

Ball bearing mounted nozzle with fast rotation,

economical cleaning

- ball bearing mounted

- fast rotation and effective cleaning

- FDA-compliant & EX certified

- high speed and fast distribution

- economical cleaning

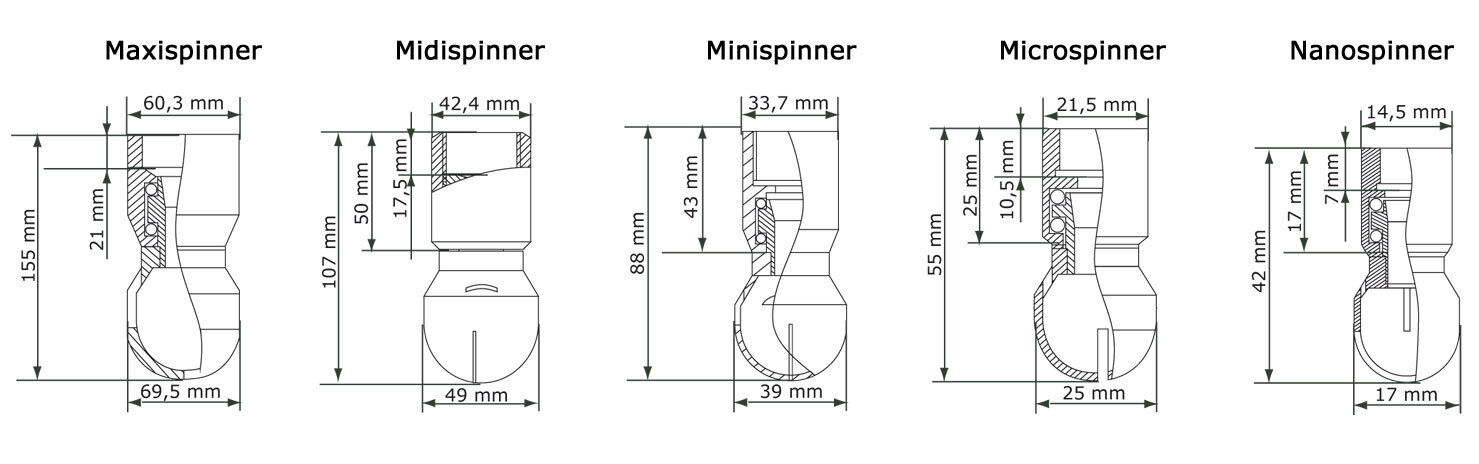

- 5 different sizes

- for hygiene sensitive applications

| Technical Data | Value |

|---|---|

| Spray pattern: | 90°, 180°, 270°, 360° up-, downwards |

| Mounting position: | arbitrary |

| Materials: | Stainless Steel 316L (1.4404), 316L (1.4401) Ball bearings, Hastelloy 2.4610 |

| Pipe connection: | BSP (NPT) |

| Optional Connection Types: | Split pin, Weld-on socket |

| Nozzle characteristics: | Ball with slots |

| Certificates: | 3.1, 2.2, ATEX, FDA, FDA Regulation (EC) No 1935/2004 |

| Materials: | Edelstahl 316L (1.4404), C.PTFE, PTFE |

| Max. operating temperature: | 90°C (194°F) |

| Max. ambient temperature: | 110°C (230°F), 30 Min. |

| Operating recommendation: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

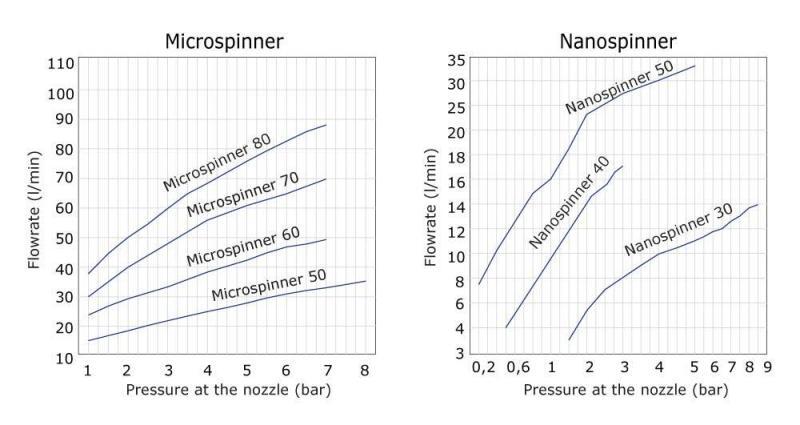

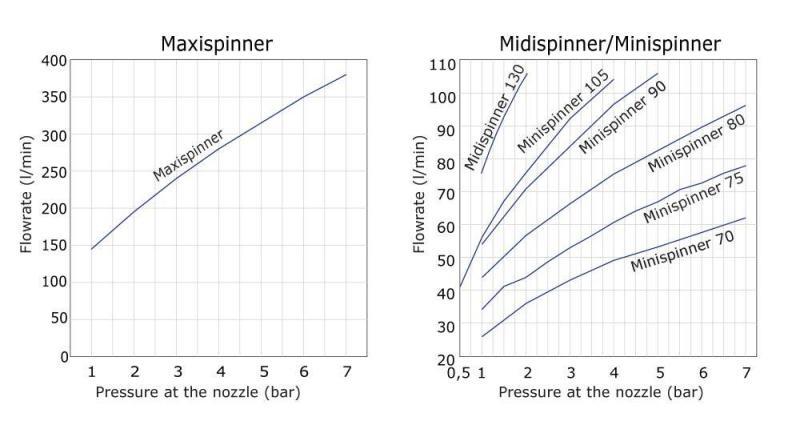

Ball bearing mounted rotary nozzles are set into rapid rotation by even low fluid pressure. The rapid rotation ensures even and full coverage distribution of the cleaning liquid. These rotary nozzles are made entirely of stainless steel, making them ideal for use in hygiene-sensitive applications in the food and pharmaceutical industries. For different requirements, these products are offered in various sizes, connection types, materials and spray angles. The liquid flow rate of a nozzle varies based on the selected size of the inlet orifice. For ball bearing rotary nozzles, we offer extensive customization in terms of connection, spray pattern and materials. Ball bearing nozzles are available in Hastelloy 2.4610.

Spinners with ball bearings are fast rotating liquid powered cleaning nozzles. While operating, liquid droplets are fully covering and distributed with the highest possible impact force. A selection of 5 different sizes and variable spray patterns is available for cleaning different types of vessels or equipment. Each size is available with different flow rates, which are determined by the size of the hole in the fluid inlet. All sizes are also available in threaded, split pin or weld-on versions. Port sizes can be customized in certain cases to meet specified needs.

By using these ball-bearing rotary nozzles, consumption values for cleaning can be saved by up to 70%. Spray pattern types of 90°, 180°, 270° and 360° down and up are available.

The stainless steel construction of these rotary nozzles ensures serviceability in sensitive FDA or pharmaceutical environments. ATEX approved versions are available (except Split pin mounting). Special polishes are offered for an additional hygienic finish.

Nanospinner

| Connection | Spray pattern | Pipe* | Product code | Materials | Certificates | Type |

|---|---|---|---|---|---|---|

| *corresponds to the max. pipe outer diameter of the pipe on which the nozzle is to be installed (inch or mm). Recommended standard devices with high stock probability are shown in blue. All thread types available as NPT. Flow rates approximately 15% higher for split pin versions. Also available with 180°, 270° and 90° downward or upward spray patterns. There is the possibility of a custom design with other spray angles, for example 320°. Polished finishes available. Spinner rotary nozzles can be made of Hastelloy 2.4610. Other customizations are possible. | ||||||

| 1/8″ IG-BSP | 360° | 1/8″ | NANO30-360-BSP | 1.4404/1.4401 | ATEX, 3.1 | 30 |

| 1/8″ IG-BSP | 360° | 1/8″ | NANO40-360-BSP | 1.4404/1.4401 | ATEX, 3.1 | 40 |

| 1/8″ IG-BSP | 360° | 1/8″ | NANO50-360-BSP | 1.4404/1.4401 | ATEX, 3.1 | 50 |

| 10,4 Split pin | 360° | 10,10 | NANO30-360-PF104 | 1.4404/1.4401 | ATEX, 3.1 | 30 |

| 10,4 Split pin | 360° | 10,10 | NANO40-360-PF104 | 1.4404/1.4401 | ATEX, 3.1 | 40 |

| 10,4 Split pin | 360° | 10,10 | NANO50-360-PF104 | 1.4404/1.4401 | ATEX, 3.1 | 50 |

| 12,3 Split pin | 360° | 12,00 | NANO30-360-PF123 | 1.4404/1.4401 | ATEX, 3.1 | 30 |

| 12,3 Split pin | 360° | 12,00 | NANO40-360-PF123 | 1.4404/1.4401 | ATEX, 3.1 | 40 |

| 12,3 Split pin | 360° | 12,00 | NANO50-360-PF123 | 1.4404/1.4401 | ATEX, 3.1 | 50 |

| 10,0 Weld On | 360° | 9,70 | NANO30-360-WO100 | 1.4404/1.4401 | ATEX, 3.1 | 30 |

| 10,0 Weld On | 360° | 9,70 | NANO40-360-WO100 | 1.4404/1.4401 | ATEX, 3.1 | 40 |

| 10,0 Weld On | 360° | 9,70 | NANO50-360-WO100 | 1.4404/1.4401 | ATEX, 3.1 | 50 |

| 12,3 Weld On | 360° | 12,00 | NANO30-360-WO123 | 1.4404/1.4401 | ATEX, 3.1 | 30 |

| 12,3 Weld On | 360° | 12,00 | NANO40-360-WO123 | 1.4404/1.4401 | ATEX, 3.1 | 40 |

| 12,3 Weld On | 360° | 12,00 | NANO50-360-WO123 | 1.4404/1.4401 | ATEX, 3.1 | 50 |

Microspinner

| Connection | Spray pattern | Pipe* | Product code | Materials | Certificates | Type |

|---|---|---|---|---|---|---|

| *corresponds to the max. pipe outer diameter of the pipe on which the nozzle is to be installed (inch or mm). Recommended standard devices with high stock probability are shown in blue. All thread types available as NPT. Flow rates approximately 15% higher for split pin versions. Also available with 180°, 270° and 90° downward or upward spray patterns. There is the possibility of a custom design with other spray angles, for example 320°. Polished finishes available. Spinner rotary nozzles can be made of Hastelloy 2.4610. Other customizations are possible. | ||||||

| 1/4″ IG-BSP | 360° | 1/4″ | MICRO50-360-BSP14 | 1.4404/1.4401 | ATEX, 3.1 | 50 |

| 1/4″ IG-BSP | 360° | 1/4″ | MICRO60-360-BSP14 | 1.4404/1.4401 | ATEX, 3.1 | 60 |

| 1/4″ IG-BSP | 360° | 1/4″ | MICRO70-360-BSP14 | 1.4404/1.4401 | ATEX, 3.1 | 70 |

| 1/4″ IG-BSP | 360° | 1/4″ | MICRO80-360-BSP14 | 1.4404/1.4401 | ATEX, 3.1 | 80 |

| 3/8″ IG-BSP | 360° | 3/8″ | MICRO50-360-BSP38 | 1.4404/1.4401 | ATEX, 3.1 | 50 |

| 3/8″ IG-BSP | 360° | 3/8″ | MICRO60-360-BSP38 | 1.4404/1.4401 | ATEX, 3.1 | 60 |

| 3/8″ IG-BSP | 360° | 3/8″ | MICRO70-360-BSP38 | 1.4404/1.4401 | ATEX, 3.1 | 70 |

| 3/8″ IG-BSP | 360° | 3/8″ | MICRO80-360-BSP38 | 1.4404/1.4401 | ATEX, 3.1 | 80 |

| 19,2 Split pin | 360° | 18,90 | MICRO50-360-PF192 | 1.4404/1.4401 | ATEX, 3.1 | 50 |

| 19,2 Split pin | 360° | 18,90 | MICRO60-360-PF192 | 1.4404/1.4401 | ATEX, 3.1 | 60 |

| 19,2 Split pin | 360° | 18,90 | MICRO70-360-PF192 | 1.4404/1.4401 | ATEX, 3.1 | 70 |

| 19,2 Split pin | 360° | 18,90 | MICRO80-360-PF192 | 1.4404/1.4401 | ATEX, 3.1 | 80 |

| 19,2 Weld On | 360° | 18,90 | MICRO50-360-WO192 | 1.4404/1.4401 | ATEX, 3.1 | 50 |

| 19,2 Weld On | 360° | 18,90 | MICRO60-360-WO192 | 1.4404/1.4401 | ATEX, 3.1 | 60 |

| 19,2 Weld On | 360° | 18,90 | MICRO70-360-WO192 | 1.4404/1.4401 | ATEX, 3.1 | 70 |

| 19,2 Weld On | 360° | 18,90 | MICRO80-360-WO192 | 1.4404/1.4401 | ATEX, 3.1 | 80 |

Minispinner

| Connection | Spray pattern | Pipe* | Product code | Materials | Certificates | Type |

|---|---|---|---|---|---|---|

| *corresponds to the max. pipe outer diameter of the pipe on which the nozzle is to be installed (inch or mm). Recommended standard devices with high stock probability are shown in blue. All thread types available as NPT. Flow rates approximately 15% higher for split pin versions. Also available with 180°, 270° and 90° downward or upward spray patterns. There is the possibility of a custom design with other spray angles, for example 320°. Polished finishes available. Spinner rotary nozzles can be made of Hastelloy 2.4610. Other customizations are possible. | ||||||

| 1/2″ IG-BSP” | 360° | 1/2″ | MINI70-360-BSP12 | 1.4404/1.4401 | ATEX, 3.1 | 70 |

| 1/2″ IG-BSP” | 360° | 1/2″ | MINI75-360-BSP12 | 1.4404/1.4401 | ATEX, 3.1 | 75 |

| 1/2″ IG-BSP” | 360° | 1/2″ | MINI80-360-BSP12 | 1.4404/1.4401 | ATEX, 3.1 | 80 |

| 1/2″ IG-BSP” | 360° | 1/2″ | MINI90-360-BSP12 | 1.4404/1.4401 | ATEX, 3.1 | 90 |

| 1/2″ IG-BSP” | 360° | 1/2″ | MINI105-360-BSP12 | 1.4404/1.4401 | ATEX, 3.1 | 105 |

| 3/4″ IG-BSP” | 360° | 3/4″ | MINI70-360-BSP34 | 1.4404/1.4401 | ATEX, 3.1 | 70 |

| 3/4″ IG-BSP” | 360° | 3/4″ | MINI75-360-BSP34 | 1.4404/1.4401 | ATEX, 3.1 | 75 |

| 3/4″ IG-BSP” | 360° | 3/4″ | MINI80-360-BSP34 | 1.4404/1.4401 | ATEX, 3.1 | 80 |

| 3/4″ IG-BSP” | 360° | 3/4″ | MINI90-360-BSP34 | 1.4404/1.4401 | ATEX, 3.1 | 90 |

| 3/4″ IG-BSP” | 360° | 3/4″ | MINI105-360-BSP34 | 1.4404/1.4401 | ATEX, 3.1 | 105 |

| 25,7 Split pin | 360° | 25,40 | MINI70-360-PF257 | 1.4404/1.4401 | ATEX, 3.1 | 70 |

| 25,7 Split pin | 360° | 25,40 | MINI75-360-PF257 | 1.4404/1.4401 | ATEX, 3.1 | 75 |

| 25,7 Split pin | 360° | 25,40 | MINI80-360-PF257 | 1.4404/1.4401 | ATEX, 3.1 | 80 |

| 25,7 Split pin | 360° | 25,40 | MINI90-360-PF257 | 1.4404/1.4401 | ATEX, 3.1 | 90 |

| 25,7 Split pin | 360° | 25,40 | MINI105-360-PF257 | 1.4404/1.4401 | ATEX, 3.1 | 105 |

| 25,7 Weld On | 360° | 25,40 | MINI70-360-WO257 | 1.4404/1.4401 | ATEX, 3.1 | 70 |

| 25,7 Weld On | 360° | 25,40 | MINI75-360-WO257 | 1.4404/1.4401 | ATEX, 3.1 | 75 |

| 25,7 Weld On | 360° | 25,40 | MINI80-360-WO257 | 1.4404/1.4401 | ATEX, 3.1 | 80 |

| 25,7 Weld On | 360° | 25,40 | MINI90-360-WO257 | 1.4404/1.4401 | ATEX, 3.1 | 90 |

| 25,7 Weld On | 360° | 25,40 | MINI105-360-WO257 | 1.4404/1.4401 | ATEX, 3.1 | 105 |

Midispinner / Maxispinner

| Connection | Spray pattern | Pipe* | Product code | Materials | Certificates | Type |

|---|---|---|---|---|---|---|

| *corresponds to the max. pipe outer diameter of the pipe on which the nozzle is to be installed (inch or mm). Recommended standard devices with high stock probability are shown in blue. All thread types available as NPT. Flow rates approximately 15% higher for split pin versions. Also available with 180°, 270° and 90° downward or upward spray patterns. There is the possibility of a custom design with other spray angles, for example 320°. Polished finishes available. Spinner rotary nozzles can be made of Hastelloy 2.4610. Other customizations are possible. | ||||||

| 1″ IG-BSP | 360° | 1″ | MIDI130-360-BSP | 1.4404/1.4401 | ATEX, 3.1 | 130 |

| 1,5″ IG-BSP | 360° | 1,5″ | MAXI400-360-BSP | 1.4404/1.4401 | ATEX, 3.1 | 400 |

| 38,4 Splint | 360° | 38,10 | MAXI400-360-PF384 | 1.4404/1.4401 | ATEX, 3.1 | 400PF |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 14.12.2022-71427321893-1888948-71042)