Fury TWB HP Jet cleaner

The Fury TWB is a powerful tank cleaner and works up to 90 bar

- effective spray strength

- low flow rates

- fast, effective cleaning

- protection against damage

- energy saving drive technology

- also available as Fury TWB version

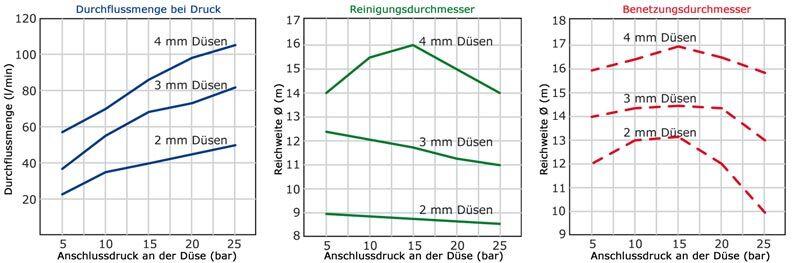

| Technical Data | Value |

|---|---|

| Max. Cleaning Diameter: | 10 meters |

| Spraypattern: | 360°, optional 180° |

| Pressure-range: | 20-90 bar |

| Flowrate: | 35 – 70 LPM (2,1 – 4,2 m³/h) |

| Insertion Opening: | min. Ø 200/120 mm (depending on the safety cage) |

| Mounting position: | vertical |

| Weight: | approx. 4,4 KG |

| Materials: | Stainless Steel 316 (1.4401), 316L (1.4404), C.PTFE, PTFE, C.PEEK, PEEK, Nitril, Viton, Kalrez |

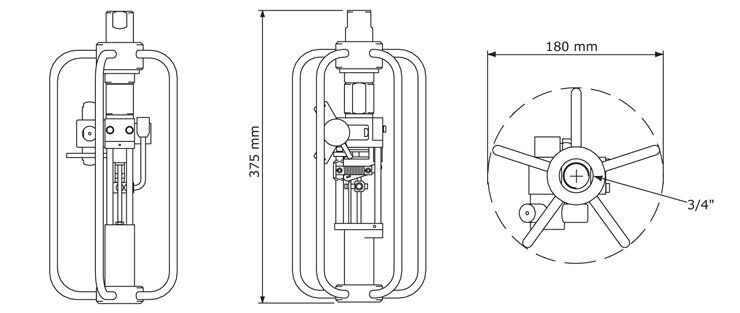

| Standard connection: | 3/4″ Female thread BSP/NPT |

| Nozzle characteristic: | 3 x 2 mm Nozzles |

| Certificates: | on demand |

| max. Operating temperature: | 120°C (248°F) |

| max. ambient temperature: | 140°C (284°F) 30 Min. |

| Operating recommendation: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

The FURY TWB HP is the high-pressure version of the FURY TWB, a powerful and water-saving tank cleaner in which the nozzles oscillate 60° while the FURY TWB HP constantly rotates around its own axis. A cage protects the tank cleaner and nozzle head from damage. The TWB is mainly used when powerful cleaning with the lowest consumption of cleaning medium is required. The drive is designed to be very easy to maintain and to minimize wear, so that the lowest possible costs and a long service life can be assumed. The FURY TWB is self-lubricating and is driven only by the force of the cleaning medium flowing through it. It has a simple drive system without high-speed turbines or gears.

The FURY TWB achieves a 360° spray pattern and is mainly used in process vessels, trucks and transport containers.

Especially in the dairy, food, beverage, pharmaceutical and chemical industries, this reliable and resource-saving container cleaner is used. The FURY TWB can be permanently mounted and can also be used in mobile applications.

The index mechanism of the FURY TWB ensures very effective and careful coverage of the spray pattern with maximum spray strength and cleaning effect.

The open design of the FURY TWB makes maintenance and inspection very easy. The FURY TWB is also available as a low pressure version!

Fury TWB HP with 3/4″ BSP thread

| Connection | Nozzle | Pipe* | Product code | Materials | Certificates | Article Number |

|---|---|---|---|---|---|---|

| *corresponds to the max. pipe outer diameter of the pipe on which the machine is to be installed (inch or mm). | ||||||

| 3/4″ IG-BSP | 3 x 2,0 | 3/4″ | FuryTWBHP-3×2-BSP | 316L/C.PEEK/C.PTFE | 3.1, 2.2 | 4660-4951-010 |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 29.10.2023-71427321893-1888948-71042)