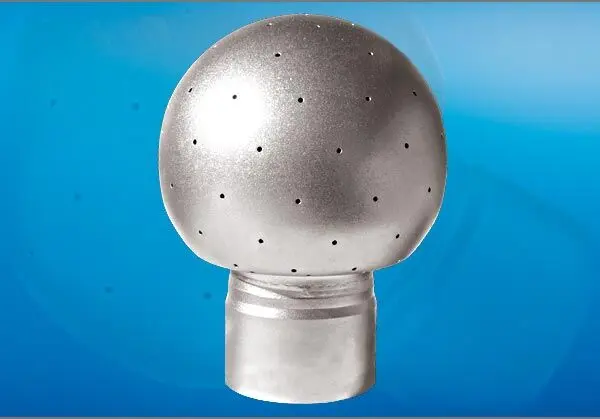

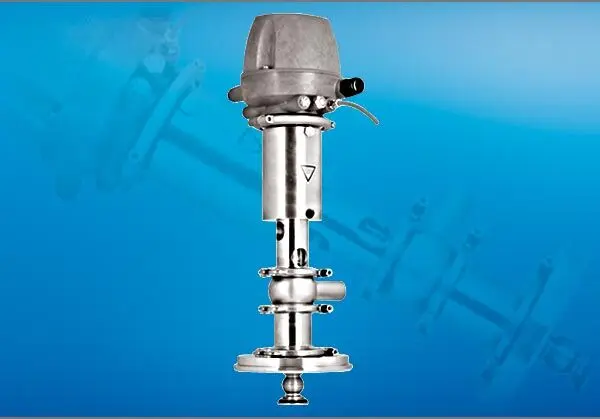

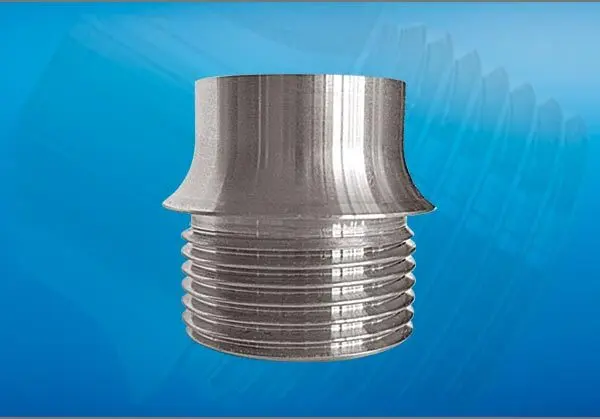

Rotating Nozzles (Jet forming) Accessories

The braked, slow rotation of our jet-forming rotating cleaners creates mutually covering, flat or bundled jets with high impact force. The slow rotation speed of these rotary nozzles is generated by a low-wear hydrostatic bearing. Our selection of jet-forming rotating nozzles is suitable for almost all low-pressure industrial cleaning applications. When operated with non-abrasive liquids, our jet-forming rotating nozzles usually achieve extremely long operating times without any maintenance or failure. We offer FDA-compliant rotating nozzles with EX exemption or EX type approval.