Torus 50/75 PEEK Rotating Nozzles

Plain bearing Nozzle with fast rotation,

extremely durable and temperature resistant

- no ball bearings

- fast rotation, effective cleaning

- FDA compliant & EX certified

- high speed, compact design

- only one moving part

- extremely heat-resistant

- low pressure condition

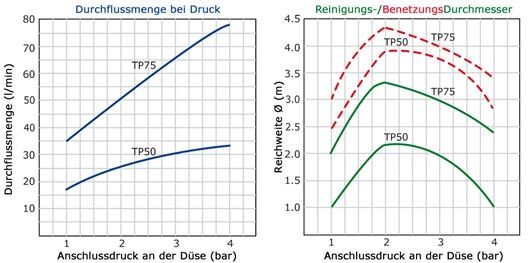

| Eigenschaft | Wert |

|---|---|

| max. Reinigungsdurchmesser | TorusP 50 2,2 Meter / TorusP 75 3,3 Meter |

| Spritzbild | 360° und 180° auf-, abwärts |

| Druckbereich | 1 – 4 bar |

| Durchflussmenge | TorusP 50 17 – 33 LPM / TorusP 75 35 – 77 LPM (1,0 – 4,6 m³/h) |

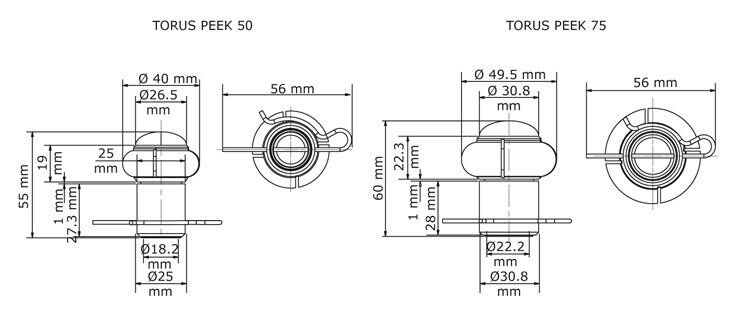

| Einbauöffnung | min. Ø 58 mm |

| Einbaulage | vertikal |

| Gewicht | auf Anfrage |

| Werkstoffe | Edelstahl 316L (1.4404), C.PEEK, PEEK, Hastelloy C22 |

| Standardanschluss | TorusP 50 DN15 Splint, TorusP 75 DN20 Splint |

| optionale Anschlusstypen | auf Anfrage |

| Düseneigenschaft | Kugel mit Schlitzen |

| Zertifikate | 3.1, 2.2, ATEX, FDA, Lebensmittelzulassung nach EU1935/2004 |

| max. Betriebstemperatur | 138°C (280°F) |

| max. Umgebungstemperatur | 250°C (482°F) |

Der PEEK Torus eignet sich optimal für die Reinigung hygienesensibler Prozessbehälter in der chemischen und pharmazeutischen Industrie. Oftmals wurden in Anwendungen dieser Industriebereiche unerfüllbare Anforderungen an die Reinigungstechnik gestellt. Kugelgelagerte Rotationsdüsen sind üblicherweise nicht für längere Druckluftbeaufschlagung geeignet, feststehende Sprühkugeln benötigen hohe Flüssigkeitsmengen und erreichen eine schlechte Reinigungseffektivität. Der PEEK Torus ist ultimativ hygienisch und resistent. Er verfügt über einen äußerst verformungssicheren, widerstandsfähigen Rotor aus PEEK. Dadurch wird maximale Beständigkeit gegenüber hohen Temperaturen oder betriebsbedingtem Abrieb erreicht.

Der PEEK Torus ist bestens für den Einsatz in Hochtemperaturbereichen und für die Heißdampfsterilisation oder eine Druckluftbeaufschlagung geeignet. Während des Betriebs wird eine schnelle Rotation des Rotors erzeugt, wodurch eine gleichmäßige und weit reichende Verteilung von Flüssigkeitstropfen stattfindet. Der Rotor ist während des Betriebs flüssigkeitsgelagert und erleidet keinen Abrieb, das Innere der Düse wird während der Reinigung stets von Flüssigkeit durchspült.

Der PEEK Torus wurde mit der pharmazeutischen und chemischen Industrie entwickelt, mit dem Fokus der absoluten Widerstandsfähigkeit für langanhaltende Dampfsterilisationen oder Trocknungsanwendungen.

In der Versuchsphase erreichte der PEEK-Torus folgende Betriebszeiten: >700 Stunden Reinigungsbetrieb: 3 bar Flüssigkeitsdruck; >350 Stunden Anwendung: Dampfsterilisation 138°C; >350 Stunden Anwendung: Trockenlauf Luftdruck 8 bar.

Nach der Versuchsphase konnten keine messbaren Verschleißerscheinungen festgestellt werden. Diese Widerstandsfähigkeit gewährleistet eine über viele Jahre zuverlässige, gleichbleibende Reinigung. Durch die Verwendung eines PEEK-Torus anstelle von feststehenden Sprühkugeln konnten unsere Kunden bereits bis zu 82% Reinigungsflüssigkeit bzw. aufzubereitende Flüssigkeit einsparen.

Der PEEK Torus ist mit PEEK oder C.PEEK Rotor erhältlich. Die C.PEEK Variante ist FDA-konform und für explosionsgefährdete Bereiche geeignet.

Der PEEK-Torus besteht aus 4 Einzelkomponenten und kann komplett zerlegt werden. Dies ermöglicht eine Reparatur oder Aufarbeitung eventuell veränderter Komponenten. Jede Komponente ist bei diesem Modell als Ersatzteil erhältlich.

Der PEEK Torus ist als Torus 50 mit DN15 und als Torus 75 mit DN 20 Splintanschluss erhältlich.

Torus 50/75 PEEK Splintanchluss

| Anschluss | Spritzbild | Rohr* | Produktcode | Werkstoffe | Zertifikate | Artikelnummer |

|---|---|---|---|---|---|---|

| *entspricht dem max. Rohraußendurchmesser des Rohres auf das die Düse installiert werden soll (Zoll oder mm). Empfohlene Standardgeräte mit hoher Lagerwahrscheinlichkeit sind blau dargestellt. 180° Varianten auf Anfrage. | ||||||

| DN15 Splint | 360° | 18,00 | TO50AFP-360-DN15 | 316L/C.PEEK | ATEX+FDA, 3.1 | – |

| DN15 Splint | 360° | 18,00 | TO50FP-360-DN15 | 316L/PEEK | FDA, 3.1 | 4660-1714-418 |

| DN20 Splint | 360° | 22,00 | TO75AFP-360-DN20 | 316L/C.PEEK | ATEX+FDA, 3.1 | 4660-1746-419 |

| DN20 Splint | 360° | 22,00 | TO75AFP-360-DN20 | 316L/PEEK | FDA, 3.1 | 4660-1746-418 |

Die dargestellten Angaben, technischen Daten und Informationen befreien den Anwender nicht von eigener Prüfung der gelieferten Produkte auf deren Eignung für den beabsichtigten Anwendungsfall. Alle Angaben sind ohne Gewähr. (Stand: 01.04.2015-71427321893-1888948-71042)