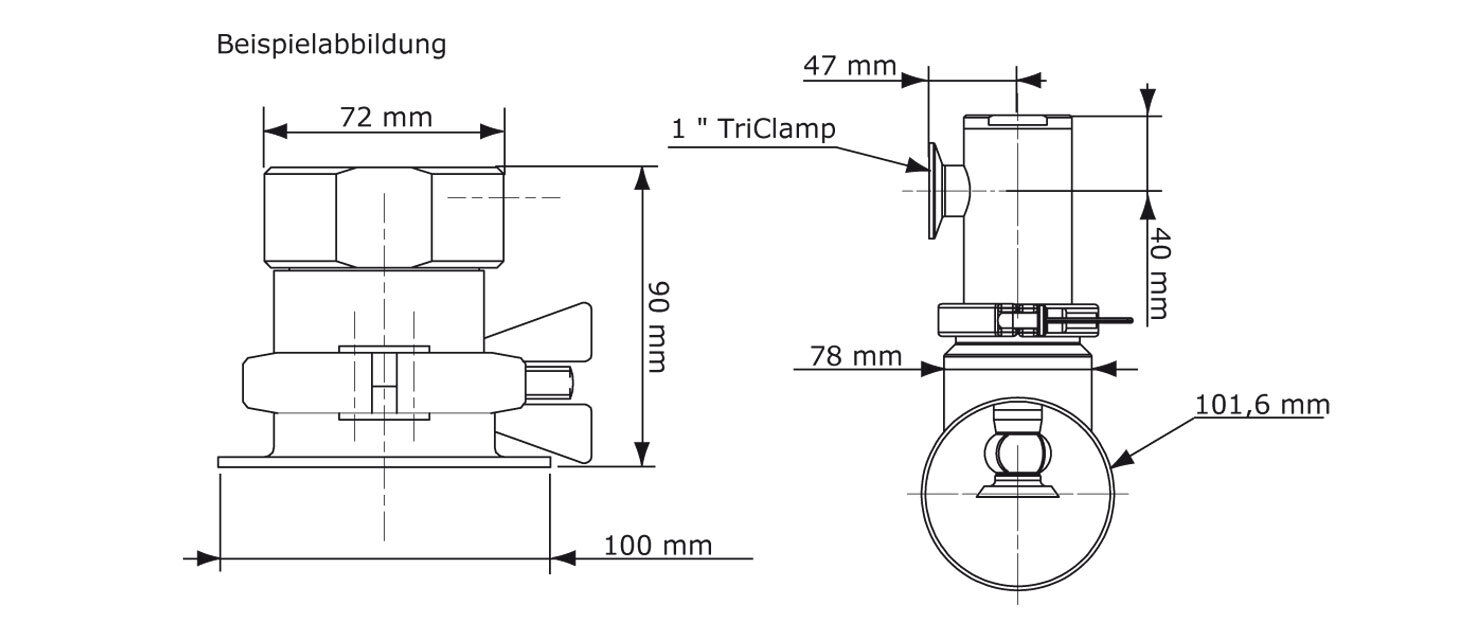

Retractor MR1

Extendable rotation nozzle with spring return

- Version with different rotation nozzles

- Return spring ensures complete closure

- FDA compliant & EX certified

- acid, alkali & temperature resistant

- adaptable design, different stroke widths

- ideal for pipelines and silos

- designed for hygienic operation

- operation monitoring by sensors possible

| Characteristic | Value |

|---|---|

| Funktion | Opening by cleaning medium, spring-closing, air/gas discharging |

| Pressure Range | 3-4 bar |

| Air pressure for emptying | ab 0,5 bar |

| Stroke lenght | 75 – 300 mm |

| Preferred mounting position | vertical downwards to horizontal |

| Weight | approx. 6,0 KG (Standard version) |

| Materials | Stainless Steel 316L (1.4404), C.PTFE, PTFE, PEEK, C.PEEK EPDM, Hastelloy, Silicon |

| Materials Feather | Stainless Steel 316 (1.4401) |

| Pipe Connection | DN25 Clamping Flange, ISO 1″ OD Clamping Flange, 1″ BS 4825-3 Clamping Flange, more on request |

| Container connection | DN65 Clamping Flange, ISO 2,5″ OD Clamping Flange, 2,5″ BS 4825-3 Clamping Flange, Block flange, Weld-on socket, more on request |

| Flange Variations | Welded flange, Welded flange R50 zu R8, more on request |

| Nozzle Characteristics | Torus (Special), Chemidisc 25-360°, Chemidisc 75-360° |

| Certificates | 3.1, 2.2, ATEX, FDA, FDA Regulation (EC) No 1935/2004 |

| Max. ambient temperature | 95°C (203°F |

| Operating recommendation: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

| MR1 Variant | Max. Cleaning Diameter | Flowrate |

|---|---|---|

| MR1 with Torus (Special) Rotor | 4,0 m | 47 – 52 LPM |

| MR1 with Chemidisc 25-360° Rotor | 1,5 m | 50 – 60 LPM |

| MR1 with Chemidisc 75-360° Rotor | 3,0 m | 75 – 83 LPM |

Retractors are extendable cleaning nozzles. By using retractor nozzles, the highest level of safety and hygiene can be achieved. Our selection of retractor nozzles includes devices with spring or compressed air retraction. Nozzle extension in these devices is usually accomplished via fluid pressure. Retractors can be equipped with static spray balls, Chemidisc and Chemitorus series slide bearing nozzles, and high-speed rotating ball bearing nozzles. The position of a retractor nozzle (open/closed) can be checked by means of a magnetic sensor. Our retractors can be adapted to individual needs. Depending on the device type, FDA conformity as well as EX exemption and stroke widths between 50 mm and 1000 mm are possible.

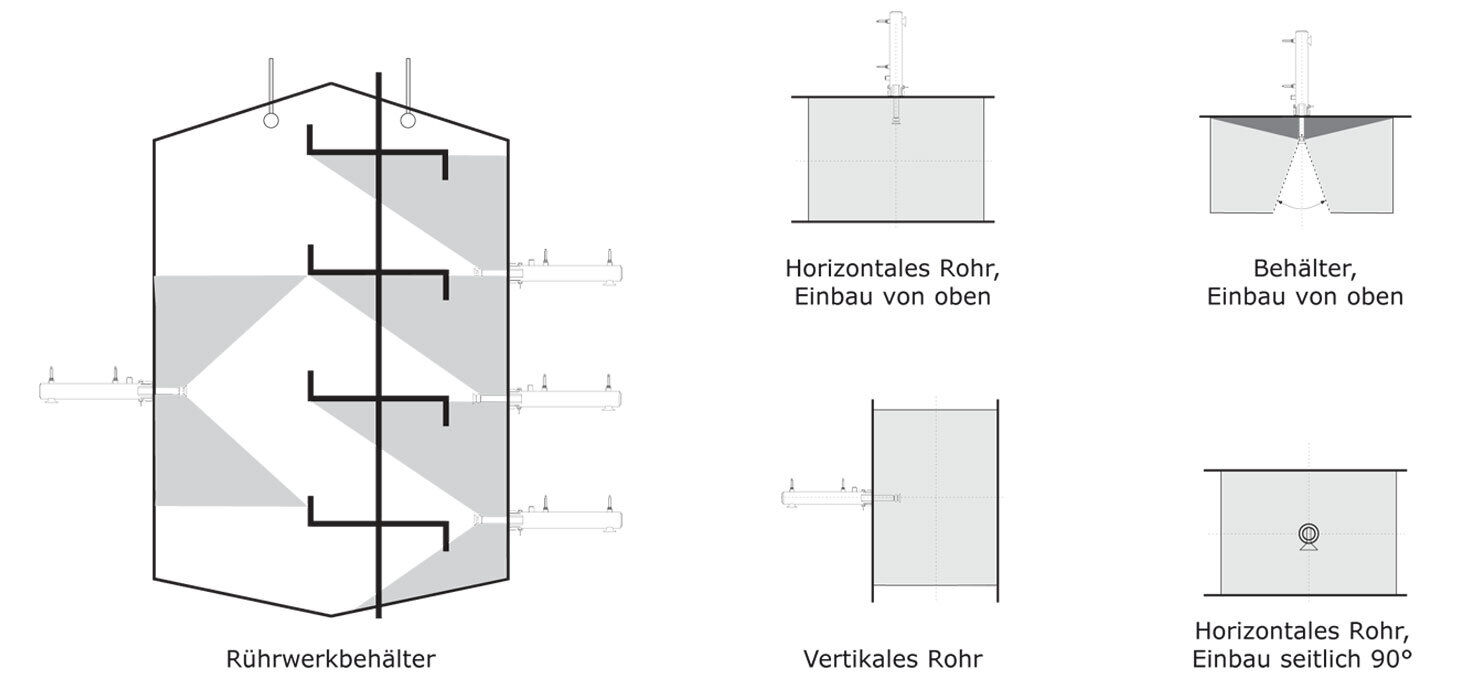

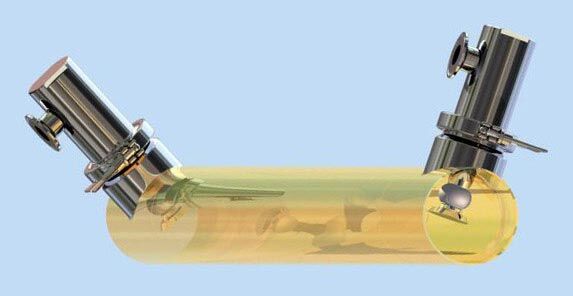

The RETRAKTOR MR1 is a retraction spring based extendable cleaning nozzle used mainly in the food, chemical and pharmaceutical industries. Using a fluid pressure of 3 bar, a rotary nozzle extends up to 300 mm into a container, pipe or equipment, allowing for targeted 270-360° all-around cleaning. The MR1 can be equipped with different nozzle sizes and types, allowing adjustments in terms of liquid flow rates or effective area. The rotating nozzle itself is fluid-bearing and extremely durable. There is a choice between a closed system (illustration) or an open system without closure to the production area.

he MR1 guarantees continuous self-cleaning during operation and can be pressurized with compressed air or steam after use for complete draining, drying or sterilization. The compressed air or steam supply must counteract the spring to achieve easy opening; complete opening is not possible. The MR1 can be used in containers with low negative pressure.

A function control can be realized optionally via magnetic proximity sensors. For mounting an MR1 to a vessel or pipe, different mounting types from 2.5″ (DN65) are possible.

The MR1 is completely made of stainless steel 316L (spring AISI316) and equipped with solvent and temperature resistant plastic components. The MR1 retractor is FDA compliant and suitable for hazardous areas (ATEX94/9/EC) and for use with flammable liquids.

The MR1 retractor can be used for liquid injection or cleaning of vessels, pipes or areas in production or filling plants.

Application areas

Installation Example

Retractor MR1 and MR2

| Code | MR1 | 100 | 1 | 1 | 2 | 1 | 1 | 1 | 0 | 1 | 0 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Position | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Example | Position | Designation | Code Selection Features | |

|---|---|---|---|---|

| MR1 | 1 | Type | MR1 | Retraktor MR1 (spring-closing) |

| MR2 | Retraktor MR2 (air-closing 1/4″ BSP IG) | |||

| 100 | 2 | Insertion lenght | 075 | 75 mm min. |

| 300 | 300 mm max. | |||

| 1 | 3 | Connections for CIP and Drainage | 1 | DN 25 Clamp flange |

| 2 | ISO 1″ OD Clamp flange | |||

| 3 | 1″ BS 4825-3 Clamp flange | |||

| other connections on demand | ||||

| 1 | 4 | Welding flange | 1 | Welded end flat |

| 2 | Welded end flat R 50 zu R ∞ (flat) on demand | |||

| 2 | 5 | Connection for welded flange | 1 | DN 65 Clamp flange |

| 2 | ISO 2 1/2″ OD Clamp flange | |||

| 3 | 2 1/2″ BS 4825-3 Clamp flange | |||

| 1 | 6 | Sprayhead | 1 | Torus (Sprayhead and Seal) |

| 2 | Chemidisc 25 | |||

| 3 | Chemidisc 75 | |||

| 1 | 7 | Seal-materials in contact with product | 1 | PTFE |

| 2 | C.PTFE | |||

| 1 | 8 | Seal-materials | 1 | EPDM |

| 2 | FKM | |||

| 4 | VMQ | |||

| 0 | 9 | Feedback | 0 | no Feedback |

| 1 | 1 magnetic proximity initiator (open) | |||

| 2 | 1 magnetic proximity initiator (closed) | |||

| 3 | 2 magnetic proximity initiator (open and closed) | |||

| 1 | 10 | Surface quality | 1 | inside Ra 0,8 μm up to Ra 1,6 μm, outside Ra 0,8 μm up to Ra 0,4 μm polished |

| others on demand | ||||

| 0 | 11 | Certificates | 0 | ohne Certificates |

| W | (41) with Factory certificate 2.2 DIN EN10204 | |||

| Z | (42) with Material inspection certificate 3.1 DIN EN10204 | |||

| S | Certificates as Set inkl. 3.1, FDA | |||

| Magnetic sensor MFT200 | Optional magnetic sensor for sensing position open and/or closed |

| _ | MR1 | MR2 | IS25 | SR1000 |

|---|---|---|---|---|

| Sprayhead | Chemidisc 25/75, Torus | Chemidisc 25/75, Torus | Spray ball (fixed) | Spinner |

| Container Connection | DN65/2,5 | DN65/2,5″ | DN80 | DN16 to DN200 |

| Extension | Fluid pressure | Fluid pressure | Air Pressure | Fluid pressure |

| Closure | Spring tension | Airpressure | Spring tension | Spring tension |

| Lifting lenght | 50 – 300 mm | 50 – 300 mm | 56 mm | 50 – 1000 mm |

| Sensor | open/closed | open/closed | No Sensor | open/closed |

| Nozzle closure | sealant | sealant | sealant | open |

| Certificates | ATEX & FDA | ATEX & FDA | FDA | FDA (ATEX) |

| Application | Pipe cleaning & Cleaning shaded areas | Container cleaning, Pipe cleaning | Pipe cleaning & Cleaning shaded areas | Container cleaning, Pipe cleaning |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All data are without guarantee. (Stand: 26.10.2023-71427321893-1888948-71042)