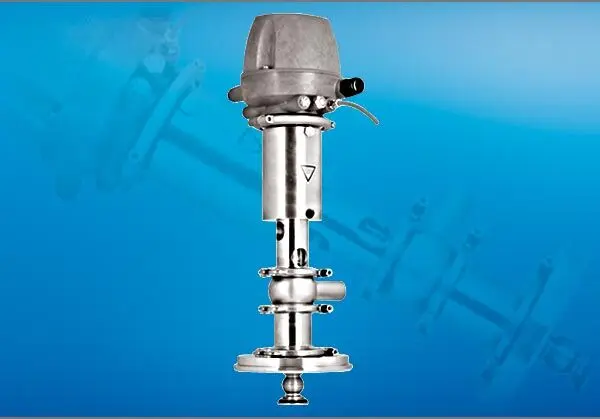

Extendable nozzles / Retractors product-overview

Retractors are extendable and retractable cleaning nozzles for vessels, piping and equipment where the nozzle cannot remain permanently in the process. Breconcherry retractor nozzles are extended primarily by fluid pressure and retracted by either a spring mechanism or compressed air. Extensive customization options are available for the connecting flanges, the stroke width, and the type of rotary nozzle (different flow rates and ranges). For use in the food and pharmaceutical industries, these cleaning machines are designed in FDA-compliant versions. For operation in potentially explosive zones or with flammable liquids, an EX exemption or an EX type examination is also available. Through the use of sensors, the function of the device can be interrogated.