Retractor IS25

IS25 retractor with static nozzle

- for hygiene sensitive applications

- numerous installation types

- enables savings on cleaning agent

- only low pressure required

- vacuum resistant up to 0.1 bar abs.

- reliable operation and low maintenance

- monitoring by proximity switch

- self-cleaning and hygienic

| Characteristic | Value |

|---|---|

| max. Cleaning diameter | 1,6 meters |

| Spraypattern | 192° – 360° |

| Pressure Range | 1,8 – 2,5 bar |

| Flowrate | 48 – 90 LPM (2,9 – 5,4 m³/h) |

| Stroke lenght | 56 mm |

| Preferred mounting position | arbitrary |

| Weight | approx. 6,0 KG |

| Materials in contact with product | Stainless Steel 316L (1.4435), EPDM, FKM, FFKM |

| Materials not in contact with product | Stainless Steel 316 (1.4301), NBR |

| Connections | see order codes |

| Nozzle characteristics | Sprayball fixed with drill holes |

| Certificates | 3.1, 2.2, ATEX 0G/20D and FDA possible |

| max. operating temperature | 98°C (208°F) |

| max. steam admission | 140°C (284°F), 30 Min. |

| max. hot air admission | 190°C (374°F), 30 Min |

| Operating recommendation | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

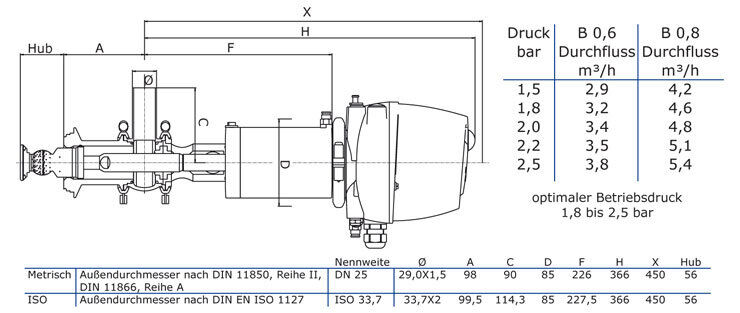

| Pressure in bar | B 0,6 Flowrate m³/h | B 0,8 Flowrate m³/h |

|---|---|---|

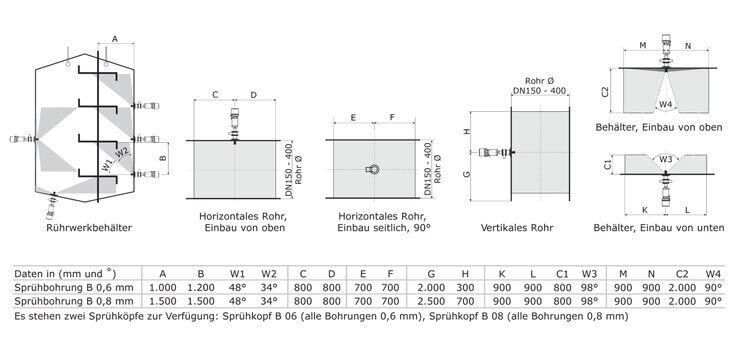

| Two spray heads are available: spray head B 06 (all 0.6 mm holes), spray head B 08 (all 0.8 mm holes). optimum operating pressure 1.8 to 2.5 bar. | ||

| 1,5 | 2,9 | 4,2 |

| 1,8 | 3,2 | 4,6 |

| 2,0 | 3,4 | 4,8 |

| 2,2 | 3,5 | 5,1 |

| 2,5 | 3,8 | 5,4 |

The advantages of the IS 25 at a glance:

- Functionally reliable and validatable

- Spring-closing and pneumatic opening

- Vacuum resistant up to 0.9 bar

- Feedback of both end positions

- Feedback via proximity switch holder or feedback head

- Seals EPDM, FKM and FFKM Solvent resistant

- Can be used in hazardous areas of ATEX zone 0G/20D

- Standard material 1.4435/316L

- Surfaces CIP and product-contact up to Ra ≤ 0.8 µm

Retractors are extendable cleaning nozzles. By using retractor nozzles, the highest level of safety and hygiene can be achieved. Our selection of retractor nozzles includes devices with spring or compressed air retraction. Nozzle extension in these devices is usually accomplished via fluid pressure. Retractors can be equipped with static spray balls, Chemidisc and Chemitorus series slide bearing nozzles, and high-speed rotating ball bearing nozzles. The position of a retractor nozzle (open/closed) can be checked by means of a magnetic sensor. Our retractors can be adapted to individual needs. Depending on the type of device, FDA conformity as well as EX exemption and stroke lenghts between 50 mm and 1000 mm are possible.

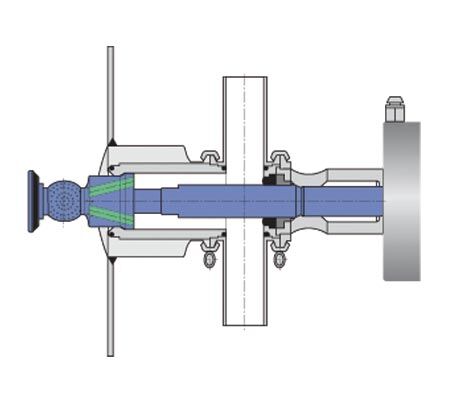

Function

During the cleaning process, the spray head is pneumatically controlled and extended. After the cleaning process, the spray head is returned to its rest position by the strong spring load from the product chamber.

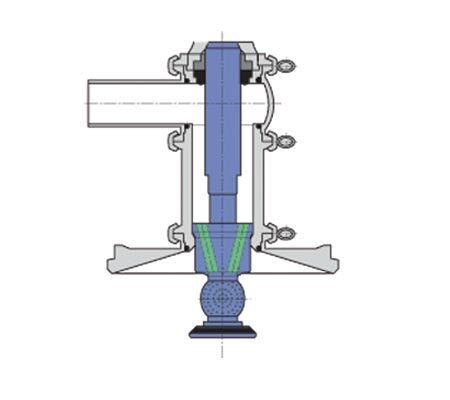

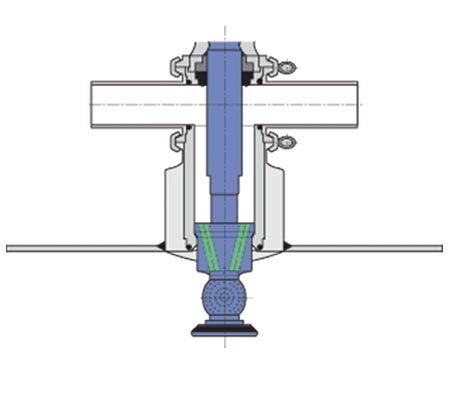

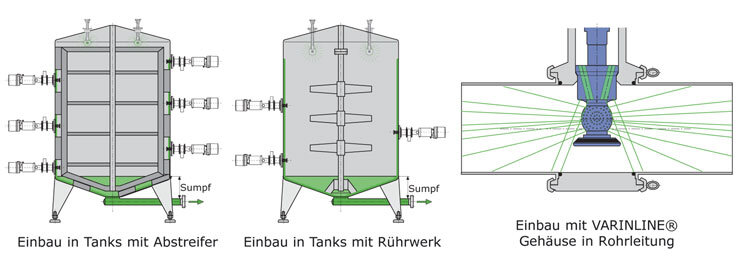

The IS25 has a spray head which is extended for cleaning in containers or pipelines. After the cleaning process, the spray head returns to its rest position and closes flush with the product chamber.

The use of the IS25 considerably reduces cleaning costs, because there is no need for buildup in agitator vessels or flooding of pipelines.

The IS25 is particularly suitable for cleaning tanks with moving internals, such as beam agitators and scrapers.

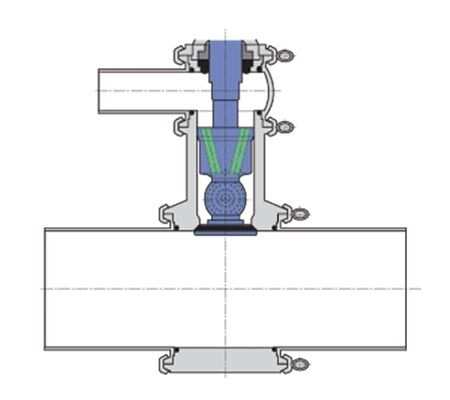

With the IS25 it is now also possible to clean bulk material pipelines with a minimized quantity, previously only possible with the use of a large quantity of cleaning agent. This considerably reduces energy and investment costs, as the cleaning agent consumption of the IS25 is only approx. 3.4 – 4.8 m³/h at 2 bar.

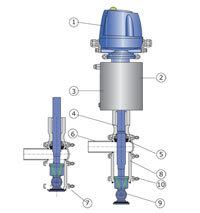

- Splash-proof connection head to protect the electrical installation (up to IP67).

- Very compact and reversible actuator – spring closing / air opening or vice versa. Air support of the spring chamber is possible.

- ECOVENT® -E actuators have the possibility of internal airflow.

- Due to the open lantern, a defective rod seal and the valve position can be recognized immediately.

- Reliable sealing at the valve stem – highest surface quality due to rolled stem surface.

- One or two-piece housing.

- The metallic stop of the valve disc results in a defined deformation of the seal. This results in a long service life.

- Seat ring and guide for the spray head.

- Removable spray head

- Easy installation and removal by means of a hinged ringSplash-proof connection head to protect the electrical installation (up to IP67).

Retraktor IS25

| Code | IS25 | D | T | 01 | 0 | 0 | 1 | K | 00 | 2 | 0 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Position | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Example | Position | Designation | Code-Selection Characteristics | |

|---|---|---|---|---|

| IS25 | 1 | Typ | IS25 | IS25 DN25 |

| D | 2 | Nominal size standard | D | DN 25 DIN (29×1,5 mm) |

| S | DIN EN ISO (33,7×2,0 mm) | |||

| T | 3 | Housing | L | 1-pruned 1.4435 |

| T | 2-pruned 1.4435 | |||

| 01 | 4 | Sprayball | 01 | Sprayhead B 0.6 |

| 05 | Sprayhead B 0.8 | |||

| 0 | 5 | Pressure Connection per Prune¹ | 0 | Welded end |

| NFK | Hygienic-Nutflange, DIN 11864-2, DIN 11853-2 | |||

| ASN | Aseptic-flange connection, DIN 11864-2 | |||

| ASK | Hygienic-flange connection, DIN 11864-2, DIN 11853-2 | |||

| AVK | Hygienic-Screw connection, DIN 11864-1, DIN 11853-2 | |||

| AVN | Aseptik-Screw connection, DIN 11864-1 | |||

| TN | VARIVENT® Nutflange incl. O-Ring and Connection parts | |||

| TK | VARIVENT® Flange connection, Nutflange on the Housing | |||

| 0 | 6 | Process connection² | 1 | Container welded flange T 50/40 1.4404 |

| 3 | Container welded flange T 50/40 1.4435 | |||

| 5 | Housing connection for VARILINE® Housing³ (DN80-150/4″-6″ OD/IPS) | |||

| 8 | anpassbarer Housing connection IS-Roh for Pipes | |||

| 2 | Housing connection IS-T 1.4435/316L | |||

| 1 | 7 | Sealing Materials in contact with product | 1 | EPDM |

| 2 | FKM | |||

| 3 | FFKM | |||

| K | 8 | Applications | K | EPDM |

| E | VMQ | |||

| 00 | 9 | Feedback⁴ | 0 | No Feedback |

| M | with Initiator admission | |||

| M2 | with Initiator admission and 2 Proximity initiators | |||

| M1 | with Initiator admission and 1 Proximity initiators | |||

| T | T.VIS® M1 feedback head with 2 feedback signals and 1 pilot valve 24V | |||

| A | ATEX feedback head ECOVENT® with 2 proximity switches 24V and 1 pilot valve 24V | |||

| 2 | 10 | Surface Quality Housing | 2 | inside Ra 0,8 μm, outside matte |

| 3 | inside Ra 0,8 μm, outside polished | |||

| 4 | inside Ra 0,4 μm, outside matte | |||

| 8 | inside Ra 0,4 μm, outside polished | |||

| 0 | 11 | Certificates | 0 | without Certificates |

| W | (41) with Factory certificate 2.2 DIN EN10204 | |||

| Z | (42) with Material acceptance test certificate 3.1 DIN EN10204 | |||

2: optional: Weld-in device, part number: 254-000271

3: VARINLINE® Housing must be ordered separately

4: further feedback selectable under T.VIS® feedback systems

| _ | MR1 | MR2 | IS25 | SR1000 |

|---|---|---|---|---|

| Sprayhead | Chemidisc 25/75, Torus | Chemidisc 25/75, Torus | Spray ball (fixed) | Spinner |

| Container Connection | DN65/2,5 | DN65/2,5″ | DN80 | DN16 to DN200 |

| Extension | Fluid pressure | Fluid pressure | Air Pressure | Fluid pressure |

| Closure | Spring tension | Airpressure | Spring tension | Spring tension |

| Lifting lenght | 50 – 300 mm | 50 – 300 mm | 56 mm | 50 – 1000 mm |

| Sensor | open/closed | open/closed | No Sensor | open/closed |

| Nozzle closure | sealant | sealant | sealant | open |

| Certificates | ATEX & FDA | ATEX & FDA | FDA | FDA (ATEX) |

| Application | Pipe cleaning & Cleaning shaded areas | Container cleaning, Pipe cleaning | Pipe cleaning & Cleaning shaded areas | Container cleaning, Pipe cleaning |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All data are without guarantee. (Stand: 26.10.2023-71427321893-1888948-71042)