Fury 400 Jet cleaner

The Fury 400 is suitable for 360° and 180° cleaning

- proven in use

- low flow rates

- short cleaning times

- also available as FURY 600 variant

- different spray patterns available

- very easy to maintain drive

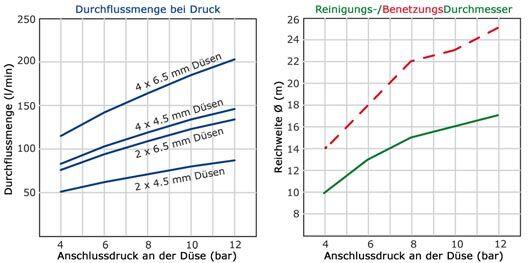

| Technical Data | Value |

|---|---|

| Max. Cleaning Diameter: | 17 meters |

| Spraypattern: | 360° and 180° up- and downwards |

| Pressure-range: | 4 – 12 bar |

| Flowrate: | 50 – 200 LPM (3,0 – 12,0 m³/h) |

| Insertion Opening: | mmin. Ø 225/140 mm (depending on the nozzle) |

| Mounting position: | vertical |

| Weight: | approx. 2,3 KG |

| Materials: | Stainless Steel 316L (1.4404), PTFE |

| Standard connection: | 1″ internal thread BSP/NPT |

| Nozzle characteristic: | 2 x 4,5 mm, 2 x 6,5 mm, 4 x 4,5 mm, 4 x 6,5 mm nozzles |

| Certificates: | on demand |

| max. Operating temperature: | 120°C (248°F) |

| max. ambient temperature: | 140°C (284°F), 30 Min. |

| Operating recommendation: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

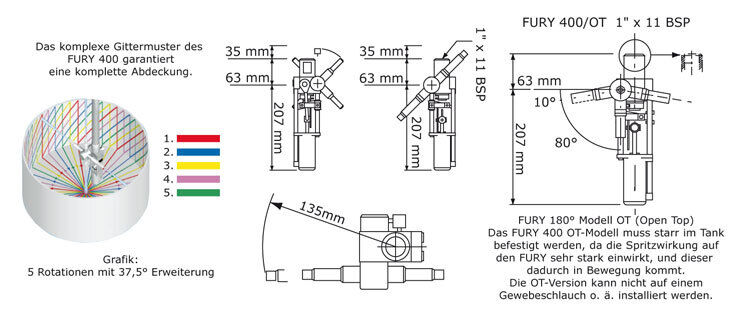

The FURY 400 is a compact cleaning device with a simple drive. In operation, the nozzles of the FURY oscillate at a 90° angle while the head of the FURY rotates around its own axis. This approach produces extremely powerful water jets with a long range. The FURY is powered solely by the cleaning fluid, using only 5% of the fluid for propulsion. The Fury 400 achieves particular effectiveness as 95% of the cleaning medium passes through the nozzles, producing maximum mechanical cleaning action.

The FURY 400’s design makes it ideal for applications where stringent hygiene and product cleanliness requirements are essential, and it is available with 180° and 360° spray patterns.

It is designed for use in process vessels, storage tanks and transport containers. The FURY tank cleaner is specifically used in beverage and dairy processing, breweries, pharmaceutical, chemical, nuclear and transportation industries. With its simple and compact design, the FURY 400 can be permanently installed as well as mobile. The FURY 400 is driven by a slow rotating piston. This makes it unique among tank cleaners in its class. Since the FURY 400 does not contain a complicated drive or high-speed turbines, it is very easy to maintain. Its specially designed nozzles produce jets with unsurpassed mechanical action. The FURY 400 convinces with guaranteed optimal cleaning results.

The slow rotation speed of the FURY 400 guarantees long-lasting use and low wear of the components. The open design of the FURY 400 makes maintenance and inspection very easy.

The minimum installation opening required to install the FURY 400 is 225 mm.

In the 2-nozzle model, the nozzles can be rotated vertically so that an installation opening of 140 mm is sufficient.

Fury 400 with 1″ BSP thread

| Connection | Nozzles | Pipe* | Product code | Materials | Certificates | Article number |

|---|---|---|---|---|---|---|

| *corresponds to the max. pipe outer diameter of the pipe on which the machine is to be installed (inch or mm). Other materials on demand. | ||||||

| 1″ IG-BSP | 2 x 4,5 mm | 1″ | Fury400-2×4-BSP | on demand | 3.1, 2.2 | – |

| 1″ IG-BSP | 2 x 6,5 mm | 1″ | Fury400-2×6-BSP | on demand | 3.1, 2.2 | – |

| 1″ IG-BSP | 4 x 4,5 mm | 1″ | Fury400-4×4-BSP | on demand | 3.1, 2.2 | – |

| 1″ IG-BSP | 4 x 6,5 mm | 1″ | Fury400-4×6-BSP | on demand | 3.1, 2.2 | – |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 27.10.2023-71427321893-1888948-71042)