Extrem starker, radial und axial rotierender motorbetriebener Zielstrahlreiniger mit 2 oder 4 Düsen

- flüssigkeitsangetriebener 360° Niederdruck-Orbitalreiniger

- extrem starke Strahlstärke und hohe Durchflussmenge

- FDA-konform & Ex-zertifiziert

- säure-, laugen- & temperaturbeständig

- kompakte Abmessungen

- selbstreinigend, hygienisch, verschleißarm

- validierbare Reinigung

- Funktionsüberwachung durch SMW 100

Technische Daten

| Technische Daten | Wert |

|---|---|

| max. Reinigungsdurchmesser | 12 Meter |

| Spritzbild | 360° orbital |

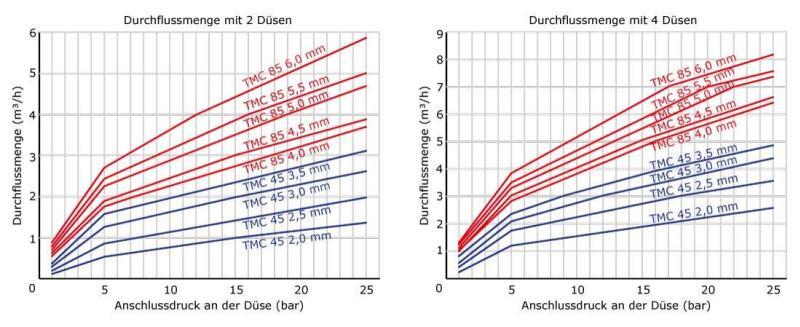

| Druckbereich | 1-25 bar |

| Durchflussmenge | 8,3 – 138 LPM (0,5 – 8,25 m³/h) |

| Einbauöffnung | min. Ø 50/96 mm |

| Einbaulage | beliebig, vertikal bevorzugt |

| Gewicht | ca. 11/15 kg |

| Werkstoffe | Edelstahl 316L (1.4404), PTFE |

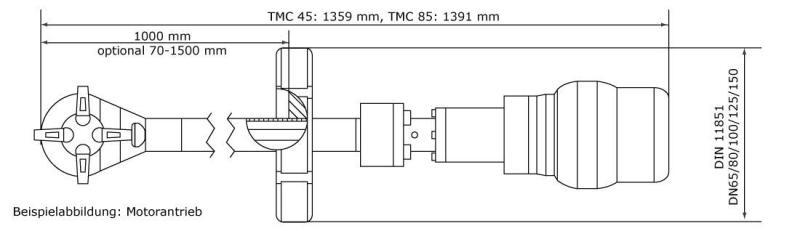

| Behälteranschluss | DIN 11851 DN65/80/100/125/150, Schwenk- und Schiebeflansch |

| Düsenbestückung | TMC 45 2 oder 4 Düsen, 2,0 bis 3,5 mm |

Betriebswerte

Optimaler Betrieb

Der Druckbereich für den Betrieb eines TMC 45/85 liegt bei 1 – 25 bar an der Reinigungsmaschine.

Mit einer Durchflussmenge von 8,3 – 138 Litern/Minute wird ein max. Reinigungsdurchmesser bis 12 Meter erreicht.

Der TMC45/85 ist ein motorisch oder pneumatisch angetriebener Orbitalreiniger der mit zwei oder vier Düsen von 2,0 mm bis 6,0 mm ausgestattet werden kann. Durch einen Motorantrieb ist die Drehzahl des axial und radial rotierenden Düsenkopfes von der Flüssigkeitsfördermenge unabhängig. Dadurch kann das Gerät schon mit geringsten Flüssigkeitsmengen eine effektive Reinigung erreichen.

Der TMC Orbitalreiniger ist in vielen Anschlusstypen und Längen erhältlich. Optional kann der Reinigungsablauf eines TMC durch SMW 100 überwacht werden.

Weitere Informationen erhalten Sie gerne auf Anfrage.

Anschlusstypen

Behälteranschluss

- DIN 11851 KM DN 65

- DIN 11851 KM DN 80

- DIN 11851 KM DN 100

- DIN 11851 KM DN 125

- DIN 11851 KM DN 150

- Schwenk- und Schiebeflansch

Reinigungsmediumanschluss

- Schweißende 21×2,5 mm

- Muffe R1/2″ Innengewinde

- Muffe R3/4″ Innengewinde

- Muffe R1″ Innengewinde

- Nippel R1/2″ Außengewinde

- Nippel R3/4″ Außengewinde

- Nippel R1″ Außengewinde

TMC 45/85 – Produktauswahl/Bestellschlüssel

TMC 45/85 motorbetriebener Orbitalreiniger

| Code | RT_TMC | 45 | 1 | S | 4 | 2 | K | 230 | – | – | – | 0 | 0 | 0 | K |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Position | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| Beispiel | Position | Bezeichnung | Code-Auswahlmerkmale | |

|---|---|---|---|---|

| * Angabe der Einführlänge ** Sonderanschlüsse auf Anfrage | ||||

| RT_TMC | 1 | Typ | RT_TMC = Orbitalreiniger TMC | |

| 45 | 2 | Baugröße | 45 | TMC 45 |

| 85 | TMC 85 | |||

| 1 | 3 | Grundpreis | 1 | Ø 21,3 mm (TMC 45) |

| Ø 33,7 mm (TMC 85) Einführlänge 500 mm | ||||

| 2 | Ø 21,3 mm (TMC 45) | |||

| Ø 33,7 mm (TMC 85) Einführlänge 750 mm | ||||

| 3 | Ø 21,3 mm (TMC 45) | |||

| Ø 33,7 mm (TMC 85) Einführlänge 1000 mm | ||||

| S | 4 | Sondereinführlänge (Aufpreis) | S | Tragrohrverkürzung/ -verlängerung |

| zwischen 200 – 1500 mm* | ||||

| 4 | 5 | Düsenscheibe | 2 | mit 2 Düsen Ø 2,0 – 3,5 mm (TMC 45) |

| 20 | mit 2 Düsen Ø 4,0 – 6,0 mm (TMC 85) | |||

| 4 | mit 4 Düsen Ø 2,0 – 3,5 mm (TMC 45) | |||

| 40 | mit 4 Düsen Ø 4,0 – 6,0 mm (TMC 85) | |||

| 2 | 6 | Düsendurchmesser TMC 45 Düsendurchmesser TMC 85 | 2 = 2 mm; 2,5 = 2,5 mm; | |

| 3 = 3 mm; 3,5 = 3,5 mm; | ||||

| 4 = 4 mm; 4,5 = 4,5 mm; | ||||

| 5 = 5 mm; 5,5 = 5,5 mm; 6 = 6 mm | ||||

| K | 7 | Einsatz | K | kein Ex-Bereich |

| E | Ex-Bereich (gilt für Zonen 1, 2, 21, 22) | |||

| 230 | 8 | Motor | 400 | Antriebsmotor 400V/50Hz; IP55; 1.400/min; 90W (ATEX) |

| 230 | Antriebsmotor 230V/50Hz | |||

| 24 | Antriebsmotor 24V inklusive Schutzhaube aus Edelstahl | |||

| P | Druckluftmotor mit Schutzhaube aus Edelstahl (ATEX) | |||

| – | 9 | Motoroptionen | – | ohne |

| F | integrierter Frequenzumrichter im Klemmkasten des Motors | |||

| – | 10 | Schutzhaube | – | ohne |

| SH | mit Edelstahlschutzhaube | |||

| – | 11 | Handgriff | – | ohne |

| H | mit Handgriff aus Edelstahl | |||

| 0 | 12 | Behälteranschluss** | 0 | ohne |

| 65 | DIN 11851 KM DN 65 | |||

| 80 | DIN 11851 KM DN 80 | |||

| 100 | DIN 11851 KM DN 100 | |||

| 125 | DIN 11851 KM DN 125 | |||

| 150 | DIN 11851 KM DN 150 | |||

| SCH | Schwenk- und Schiebeflansch | |||

| 0 | 13 | Anschluss Reinigungsmedium | 0 | Schweißende 21×2,5 mm |

| 1 | Muffe R1/2″ Innengewinde | |||

| 2 | Muffe R3/4″ Innengewinde | |||

| 3 | Muffe R1″ Innengewinde | |||

| 4 | Nippel R1/2″ Außengewinde | |||

| 5 | Nippel R3/4″ Außengewinde | |||

| 6 | Nippel R1″ Außengewinde | |||

| 0 | 14 | Oberfläche | 0 | Ra < 0,8 μm geschliffen (ohne Schweißnähte) |

| 1 | Ra < 0,4 μm elektropoliert (ohne Schweißnähte etc.) | |||

| K | 15 | Zertifikate | K | ohne Zertifikate |

| W | (41) mit Werkzeugnis 2.2 DIN EN10204 | |||

| Z | (42) mit Material-Abnahmeprüfzeugnis 3.1 DIN EN10204 | |||

| A | (41/42) 2.2; 3.1 | |||

Zubehör

SMW 100 Flüssigkeitssensor

| Werkstoffe: | 1.4305, PEEK |

| Anschlusstyp: | Einschweissmuffe |

| Funktion: | Die Beschwallung des Sensors wird alle 20 Sekunden angezeigt |

Ersatzteile & Werkzeug

| TMC 45 Maschinenkopf | 254-000537 |

| TMC 85 Maschinenkopf | 254-000538 |

| TMC 45/85 Kupplung | 254-000539 |

| Werkzeugsatz TMC 45: | 254-000566 |

| Werkzeugsatz TMC 85: | 254-000568 |

Die dargestellten Angaben, technischen Daten und Informationen befreien den Anwender nicht von eigener Prüfung der gelieferten Produkte auf deren Eignung für den beabsichtigten Anwendungsfall. Alle Angaben sind ohne Gewähr. (Stand: 16.10.2023-71427321893-1888948-71042)